|

|

Post by goldvic on Nov 23, 2012 9:38:34 GMT 12

HI All new to the board. Firstly i live in Colombia South America. I have built my own 9" wide sluice box with high banker. Why ---cause this is not stuff you can buy off the self so no choice but to make my own. I have now converted the sluice box into a suction dredge My idea is to set it next to a small creek and suck out from underneath the big boulders. I have a 2" Briggs and Stratton 3.5 HP pump which delivers 150 GPM It appears to be supplying more than enough pressure and flow. Now to the problem my DIY suction nozzle. I made it out of 2" PVC and the water supply at 1 1/4" I hope you can see the photo. I have water coming out the nozzle tip and also a good flow at the sluice box The problem is that it is not sucking it is pouring water out of the nozzle tip. Can anyone offer some advice Thanks in advance have a look at my flicker page www.flickr.comvicshere2002 here you can see more photos and videos of my area and my rig in action i hope it works Attachments:

|

|

|

|

Post by goldvic on Nov 25, 2012 8:27:33 GMT 12

47 views and no replies is it that bad?  ?? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 25, 2012 9:35:33 GMT 12

Hi Goldvic,

Havnt had experience with these for quite some time.

Is your venturi a jet, a taper down to create a jet?

Also try taking the last bit of the nozzle off and try that.

Cheers

Mark

|

|

|

|

Post by treeman on Nov 25, 2012 9:38:09 GMT 12

try half inch jet, you are putting to much water through, if there is to much it fills the pipe and creates poor suck and flows out nozzle.

to small and it will not have enough grunt so no suck again.

you need to get it right. so try half inch jet.

I have an old 5'' and its nozzle jet size is five eights inch.

|

|

|

|

Post by RKC on Nov 25, 2012 10:55:47 GMT 12

|

|

|

|

Post by goldvic on Nov 25, 2012 12:04:43 GMT 12

great info tomorrow i will try to reduce the pressure inlet down to maybe 3/4" then report back

thanks

|

|

|

|

Post by goldvic on Nov 26, 2012 10:33:45 GMT 12

UPDATE well i made a reducer from 1 1/4" to 1/2 inch i am getting suction at the nozzle and water coming out at the sluice but it doesn't seem to be sucking up 1/4" stones. If i put my hand over the nozzle it has good suction everything was appearing to run ok until my water supply hose running from my pump exploded. Well guess that hose doesn't like that pressure. Tomorrow going out to find the 2" flat hose which i am sure will hold up the pressure Do you think i need to go smaller than 1/2" for more pressure?? Attachments:

|

|

|

|

Post by goldvic on Nov 26, 2012 10:34:37 GMT 12

another pic Attachments:

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 26, 2012 10:37:40 GMT 12

Hi Goldvic,

It needs to taper creating a jet, not a reducer.

Cheers

|

|

|

|

Post by goldvic on Nov 26, 2012 12:35:24 GMT 12

a taper you say

humm my next huddle

make a tapered reducer

give me a couple of days

Thanks for advice

|

|

|

|

Post by goldvic on Nov 29, 2012 9:39:11 GMT 12

ok took you advice and i created a taper nozzle here is my design which the machine shop used to turn it out of 1 3/4 D plastic propylene will assemble it tomorrow and test it out Attachments:

|

|

|

|

Post by goldvic on Dec 5, 2012 5:06:29 GMT 12

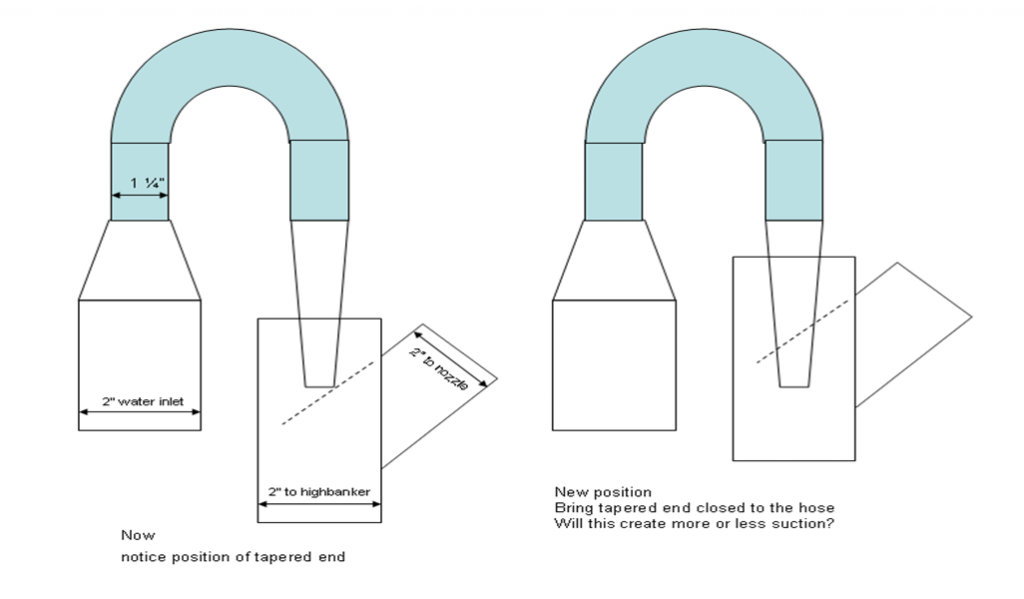

Well an update This past Sunday I went to the river to try my new self made/designed dredge system. I took the advice from "homesouth" and had a tapered nozzle made as per my diagram above. I had a couple of problems. But first I would have to say I think my water pressure is correct as the flex hose is hard as a rock and I cant even press into it with my thumb. I think I am getting sufficient water flow out on my sluice box. If you see the videos I know I have to shift the high banker a bit back as my water was shooting out past my lower sluice box. That’s an easy fix. Now for my major problem. When I first started using the nozzle it appeared to be sucking up sand and I could see it going down the hose and into the high banker. But after like 5 minutes I noticed the the sand stopped flowing down the hose. I further inspected the nozzle end and saw that it was plugged with sand. As soon as I lifted the nozzle end a bit out of the water the sand would kind of slide back into the hose and then continue on to the high banker. So I fond myself for the next hour or two sticking the nozzle into the sand and lifting it out of the water to get my material to the high banker. it appears the water pressure is enough to push the material up the hose but not enough to create a strong suction. Don’t think this is what I am seeing on dredge video on YouTube. So I am think of moving the tapered end down into the "Y" a bit more. (see diagram # 1 below) Do you think this will create more suction? Or do you think I should make a new tapered end smaller tip hole diameter. Another question, is my tapered end long enough at 6" or does it need to be longer? I am now at 15MM maybe drop it down to 11-12MM?  Thanks so much for your help! video # 1 youtu.be/HiZvtxRxIz8video # 2 youtu.be/ohOSf9l5FQkNew diagram # 1  My nozzle screen  other pics     |

|

|

|

Post by treeman on Dec 5, 2012 22:40:05 GMT 12

don't use new position of taper it will just block the jet.

2" pipe has to be clear all the way.

cheers

|

|

|

|

Post by goldvic on Dec 6, 2012 0:08:51 GMT 12

so your saying that a 2" hose needs to go all the way to the 1 3/8" tapered flare? But what i see in photos for example  is the incoming pipe which looks very small up to the "flare" now i am confused. I could try that or maybe make a a new flare which goes from 1 3/4" to 1/2" and take a 2" hose all the way to the beginning of the flare would that be a better fix? Thanks for your input |

|

|

|

Post by RKC on Dec 6, 2012 10:03:38 GMT 12

|

|